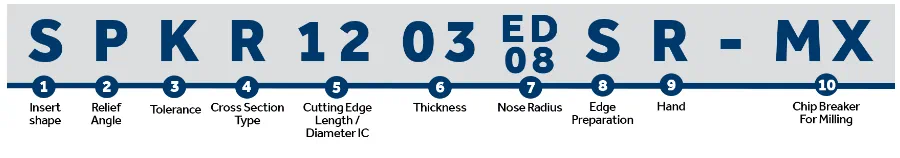

Lokacin da kuka ga abin yankan niƙa, zaku iya ci karo da kalmar "lambar ISO." Amma menene ainihin ma'anar wannan lambar? Wane sako yake aikawa? Fahimtar lambar ISO don shigar da niƙa yana da mahimmanci don zaɓar kayan aikin da ya dace don aikin niƙa kuma samun sakamako mafi kyau.

Ko kai ƙwararren masani ne da ke neman faɗaɗa ilimin ku, ko kuma sabon mai neman aikin niƙa, wannan jagorar za ta lalata lambar ISO don abin da ake sakawa a nan.

Za mu bincika fassarar lambar, yadda lambar ke fassara mahimman bayanai game da lissafi, abu, da halaye na yankan abin da aka saka. A ƙarshe, za ku sami ilimin fassara lambar, yana ba ku damar zaɓar cikakkiyar abin da ake saka niƙa don inganta aikin injin ku.

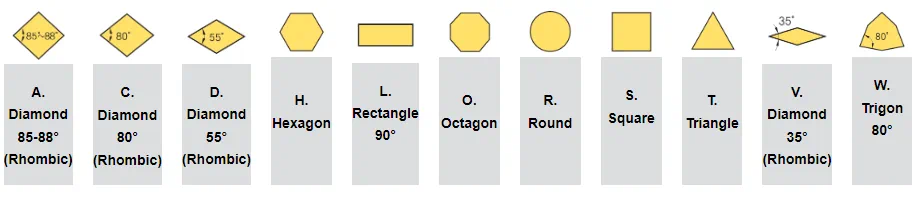

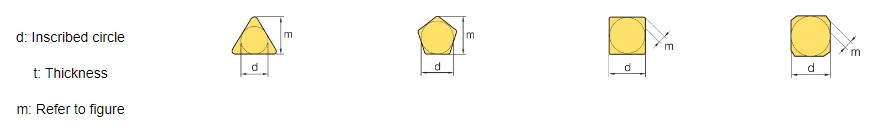

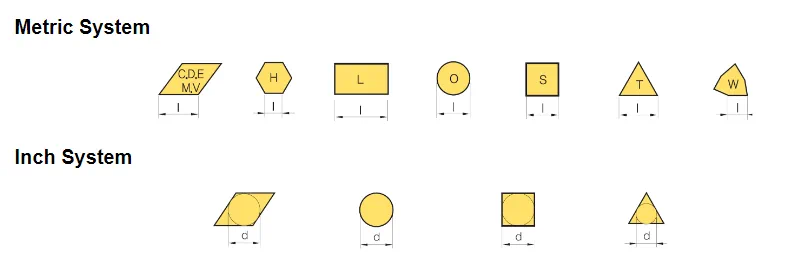

1.Siffar ruwa

Sashi na farko na lambar ISO don abin da ake sakawa shine game da saka siffa da salo.

Yana farawa da harafin da ke nuna sifar ruwa, kamar R don zagaye, S don murabba'i, T don alwatika, D don lu'u-lu'u, ko C don lu'u-lu'u.

Wannan yana ba da bayani game da gaba ɗaya nau'in ruwa, yana taimakawa tare da ganowa cikin sauri. Ta hanyar kallon harafin farko na milling saka lambar ISO, yana yiwuwa a sami ra'ayi na farko na siffar abin da ake sakawa, wanda ke taka muhimmiyar rawa wajen tantance takamaiman aikace-aikacen sa da yanke damar.

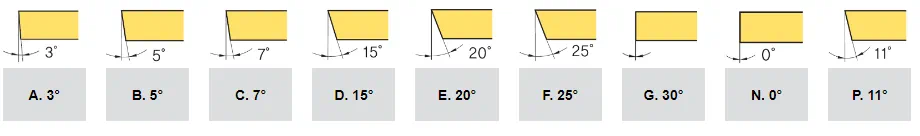

2.Blade na baya kusurwa

Harafi na biyu na milling saka ISO ƙayyadaddun bayanai yana nufin kusurwar baya na abin da aka saka.

Niƙa kusurwar baya yana da mahimmanci don ingantacciyar ayyukan injuna.

Yana taka muhimmiyar rawa a cikin samuwar guntu, rayuwar kayan aiki, yanke ƙarfi da gamawa. Fahimtar tasirin kusurwar baya da zabar madaidaicin kusurwar baya na iya haɓaka aikin sarrafawa, yawan aiki da ingancin samfurin gama.

3.Tolerance

Matsayi na 3 yana ƙayyadad da juriyar abin da ake saka niƙa.

Haƙuri yana nufin bambancin da aka yarda a cikin girman ko ƙimar auna ɓangaren da aka ƙera. Matsayin haƙuri da aka ƙayyade a cikin matsayi na ISO 3 don abubuwan da ake sakawa na niƙa yana taimakawa wajen tantance daidaiton girman abin da aka saka da ƙimar ingancin mashin ɗin akai-akai.

Hakuri na niƙa ruwan wukake na da mahimmanci saboda dalilai da yawa. Da farko, yana tabbatar da dacewa mai dacewa da dacewa tare da mai riƙe kayan aiki, yana inganta kwanciyar hankali da aminci yayin yin aiki. Na biyu, madaidaicin haƙuri yana ba da gudummawa ga daidaiton ƙima, yana ba da damar samun tabbataccen sakamako na inji.

Bugu da kari, m haƙuri yana ba da damar musanyawa tsakanin tsarin kayan aiki, yana rage raguwar lokaci. Har ila yau, suna shafar rayuwar kayan aiki da aiki, kazalika da ƙarewar ƙasa da daidaito.

4.Nau'in Sashe

Matsayin ISO 4 yana nufin nau'in sashe na milling.

Nau'in juzu'in abin saka niƙa yana nufin sifar yankansa idan an duba shi daga kusurwar tsaye. Yana rinjayar aikin yankewa da aikin ruwa.

Nau'o'in sassan giciye na gama gari sun haɗa da murabba'ai, da'ira, triangles, rhomboids, da pentagons. Masu inji yakamata suyi la'akari da nau'in sashin giciye lokacin zabar abin da aka saka don tabbatar da mafi kyawun iya yankewa da cire guntu don takamaiman ayyuka da kayan aikinsu.

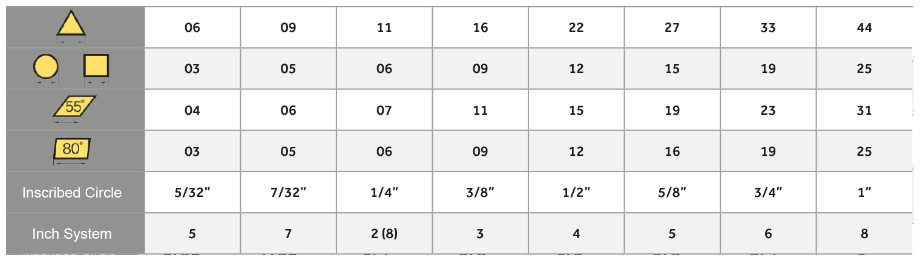

5.Cutting gefen tsawon / diamita IC

Matsayi na 5 yana ba da cikakkun bayanai game da girman abin da ake sakawa niƙa ko tsayin yankan.

Matsakaicin tsayin tsayin daka mai niƙa muhimmin abu ne wanda ke shafar aikin yanke kai tsaye da ingancin abin da aka saka.

Tsawon tsayin yankan yana ba da izinin yanki mafi girma tsakanin ruwan wukake da kayan aiki, don haka ƙara yawan aiki da haɓaka cire kayan. Yana ba da damar shigarwa don saduwa da babban yanki na kayan abu, yana rage adadin waƙoƙin injin da ake buƙata don kammala aikin injin.

Sabili da haka, zabar tsayin tip mai dacewa yana da mahimmanci don cimma kyakkyawan aikin yankan, haɓaka yawan aiki da tabbatar da aikin niƙa mai tsada.

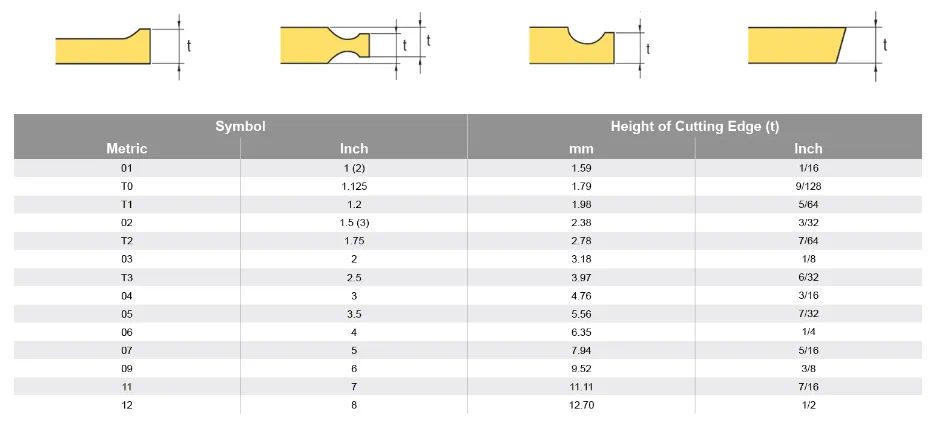

6.Kauri

Matsayi na 6 yana fayyace kaurin abin da aka saka niƙa.

A cikin tsarin yankan, kauri na saka yana da mahimmanci ga ƙarfinsa da kwanciyar hankali. Abubuwan da aka saka masu kauri suna aiki da kyau a ƙarƙashin kaya masu nauyi, haɓaka aiki da rage haɗarin yanke ɓarke .

Gabaɗaya, ruwan wukake masu gefe biyu (mara kyau) suna da kauri fiye da ruwan wukake mai gefe guda (tabbatacce).

Sabili da haka, zabar kauri mai kyau yana da mahimmanci don cimma mafi kyawun aikin yankan, yawan aiki da ingancin da ake so na sassa na inji.

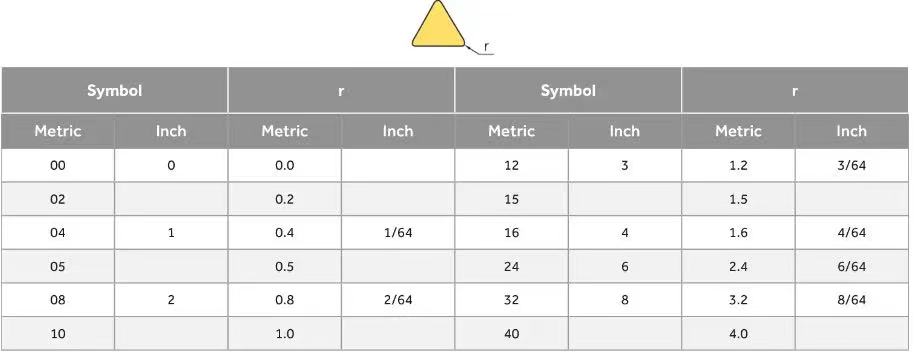

7.Tip fillet radius

Zuwa lamba 7, za mu ci karo da bayani game da radius na ruwa.

Radius na saka niƙa yana da mahimmanci don daidaitattun ayyukan mashin ɗin, yayin samun damar amfani da radius zuwa yankan ku. Ƙananan radius suna nuna fifikon yankewa / ƙarewa, yayin da manyan radiyoyin sun fi dacewa da cire ƙarfe mai nauyi saboda ƙarfin kusurwar ruwa.

Har ila yau, radius yana rinjayar ikon yankewa na sakawa, sarrafa guntu, rayuwar kayan aiki, da kuma ƙarewa. Yin la'akari da hankali na radius na hanci daidai bisa ga ƙayyadaddun buƙatun machining da kayan aiki yana da mahimmanci don cimma kyakkyawan aiki, rayuwar kayan aiki da ƙarewa a cikin ayyukan milling.

8.Bayanan ruwa

Milling saka ISO 8 yawanci yana ba da bayanai game da ruwa.

Shirye-shiryen ɓangarorin abin da ake saka niƙa yana nufin ƙarin jiyya na niyya na gefen abin da aka saka kafin a yi amfani da shi wajen aikin niƙa. Ya ƙunshi yin amfani da takamaiman magani ko sutura don haɓaka aiki da dorewa na ruwa.

Ta hanyar zaɓar a hankali da amfani da fasahar gefen da ta dace, masana'antun za su iya haɓaka aikin injin, yawan aiki, da rayuwar kayan aiki yayin da suke ci gaba da ƙoshin ingancin ƙasa da daidaiton ƙima.

Hoto

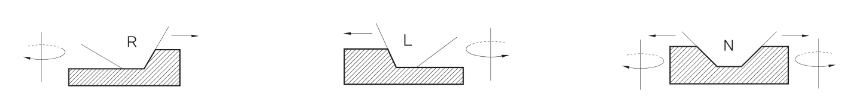

9.Hagu na hannun hagu, ruwan hannun dama

Jagoranci ko alkiblar yankan ɓangarorin abin yankan niƙa da siffar da ta dace.

Yana ƙayyade ko an ƙera ruwan wukake don juya hannun dama (hannun agogo) ko na hagu (ƙi da agogo) yayin niƙa.

Yin amfani da abubuwan da aka saka tare da madaidaicin daidaitawar hannu yana da mahimmanci don ingantaccen sakamako na injina.

10.Chip karya trough zane

Lamba 10 yana nuna ƙirar tsinke guntu.

Ƙirar ƙwanƙwasa ƙirar niƙa tana nufin siffa ta musamman da aka ƙera a saman abin da ake sakawa da kuma yankewa yayin aikin niƙa, wanda ke taimakawa wajen sarrafa samuwar guntu.

Yana taka muhimmiyar rawa wajen sarrafa guntu, rage samuwar toshewar guntu, manne kayan aiki da gina guntu.

Ƙirar ɓoyayyen guntu da aka ƙera yana da mahimmanci don tabbatar da tsari mai santsi kuma abin dogara.

Takaitawa

Fahimtar lambar ISO don abubuwan da ake sakawa kamar ɓata yaren sirri ne wanda shine mabuɗin samun nasarar ayyukan niƙa da zaɓin kayan aiki.

Kowane bit na lambar yana ba da fa'ida mai mahimmanci cikin sifar ruwa, girma, juriya da ƙimar kayan abu.

Ta hanyar bayyana ma'anar da ke bayan kowane bangare, mashin ɗin zai iya amincewa da zaɓin abin da ya dace na niƙa, tabbatar da dacewa tare da saitunan mashin, kuma cimma sakamakon da ake so dangane da aiki, daidaito, da rayuwar kayan aiki.

Tare da wannan ilimin, kuna shirye don yanke lambar saka lambar ISO kuma buɗe yuwuwar aikin niƙa ku.

BAYAN LOKACI: 2024-11-17