Anyị na-akpọga gị n'ebe nrụpụta WATT Carbide na Zhuzhou ka ị hụ ka esi etinye ntinye. Lee ka esi eme ya!

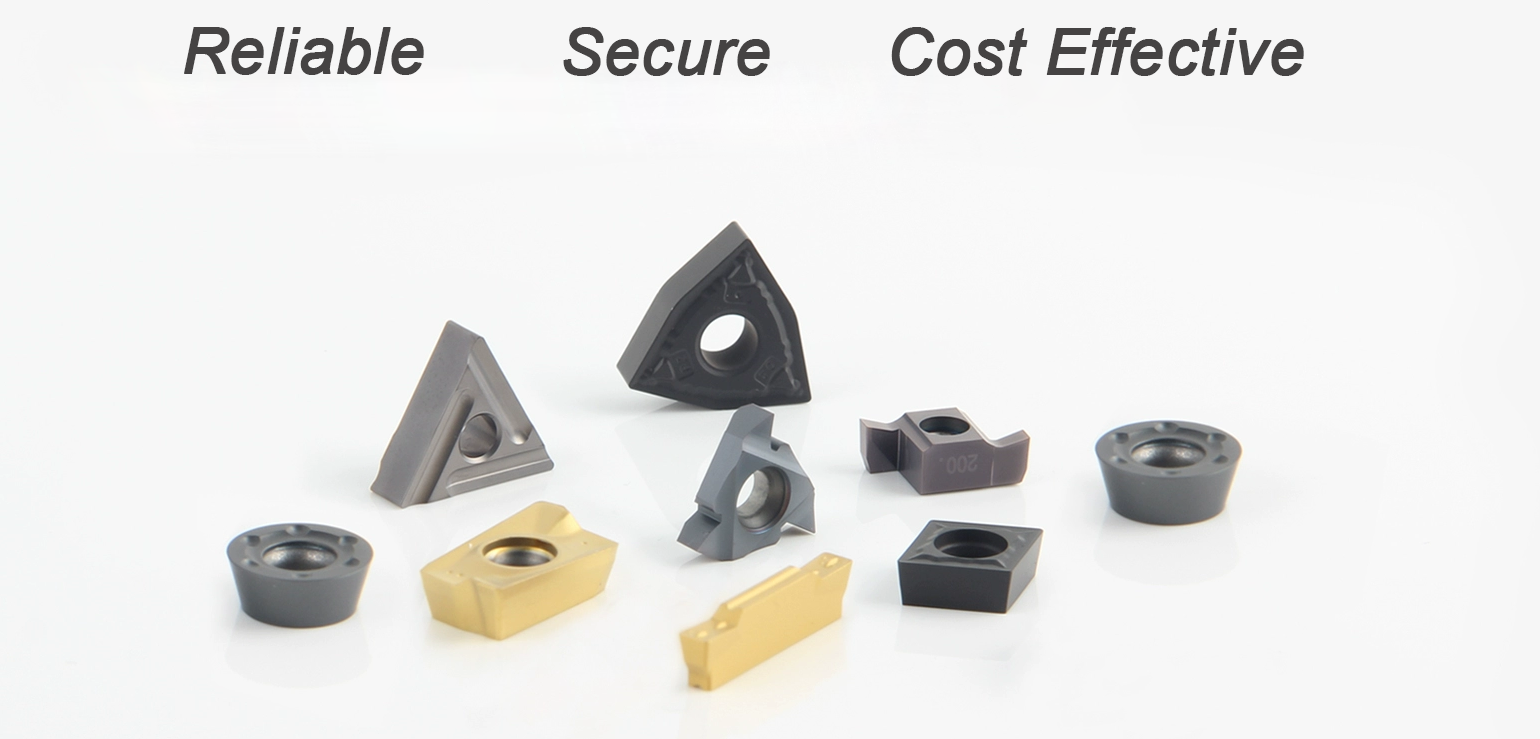

Ederede ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla emere ọla ka ejiri ihe ntinye rụọ ọrụ. Ihe ntinye ahụ aghaghị iguzogide oke okpomọkụ na ike, ya mere a na-eme ya nke ụfọdụ ihe siri ike n'ụwa.

Ihe ntinye a na-ahụkarị bụ nke 80% tungsten carbide na matrix metal nke na-ejikọta mkpụrụ osisi carbide siri ike ọnụ, ebe cobalt bụ ihe a na-ahụkarị. Ọ na-ewe ihe karịrị ụbọchị abụọ iji mepụta ntinye, ya mere ọ bụ usoro mgbagwoju anya.

N'ụlọ nkwakọba ihe, a na-akwakọba ahịrị mgbe ahịrị akụrụngwa. Carbide tungsten anyị na-eji sitere na ndị na-ebubata ngwaahịa ahọpụtara nke ọma; A nwalere ogbe ọ bụla nke ọma na ụlọ nyocha. Ezi ntụziaka nwere obere ihe ahọpụtara nke ejiri aka gbakwunyere. A na-ekesa ihe ndị bụ isi na-akpaghị aka na nkwụsị dị iche iche n'akụkụ ahịrị nha. N'ime ụlọ a na-egwe ọka, a na-eji ethanol, mmiri na ihe na-ekekọta ihe ndị na-emepụta ihe na-egweri na nha nke achọrọ.

Usoro a na-ewe site na asatọ ruo 55 awa, dabere na uzommeputa. A na-agbaba slurry ahụ n'ime igwe na-agba mmiri ebe a na-efesa gas nitrogen na-ekpo ọkụ iji wepụ ethanol na ngwakọta mmiri. Mgbe ntụ ntụ ahụ kpọrọ nkụ, ọ na-enwe granules dị okirikiri nke nha ya. A na-eziga ihe nlele na ụlọ nyocha maka ịlele ịdị mma. Barrel nke kilogram 100 nke ntụ ntụ dị njikere maka ịpị na-abata n'igwe a na-akụnye. Ihe nkedo agbakwunyere n'ime ụlọ igwe nri bụ ihe nkedo na-ejikọta ntụ ntụ mgbe ịpịrị ya.

A na-etinye ihe ruru tọn 12 nke nrụgide, dabere n'ụdị ntinye. Ihe nkedo agbakwunyere n'ime ụlọ igwe nri bụ ihe na-ejikọta ntụ ntụ mgbe ịpịrị ya. Usoro a na-akpaghị aka kpamkpam. A na-atụ ihe ntinye ọ bụla yana n'oge ụfọdụ nke onye ọrụ na-achịkwa anya ya. Ihe ntinye ndị a na-agbanye na-esighi ike ma ọ dị mkpa ka a sie ike na oven nke na-ekpo ọkụ. Usoro a na-ewe ihe dị ka awa 13 na okpomọkụ nke ihe dịka 1,500 degrees Celsius. A na-agbanye ihe ndị ahụ n'ime ngwaahịa simenti-carbide siri ike nke ukwuu, ọ fọrọ nke nta ka ọ siri ike dị ka diamond.

A na-esure ihe nkedo organic ọkụ na ntinye ya na-agbada ihe dị ka ọkara nha mbụ ya. A na-emegharị oke okpomọkụ ma jiri ya kpoo ụlọ ahụ n'oge oyi, ma mee ka ha dị jụụ n'oge okpomọkụ. Ihe ntinye a na-agbanye n'otu n'otu, n'ụdị igwe egweri dị iche iche iji nweta nha kpọmkwem, geometry na ndidi. Dị ka ihe ntinye carbide simented siri ike, diski nwere 150 nde obere diamond ụlọ ọrụ, na-egweri ya. A na-emegharị ihe karịrị carbide, yana mmanụ a na-eji egbutu mmiri.

A na-ekpuchi ihe ka ukwuu n'ime ihe ntinye, ma ọ bụ site na ntinye nke vapor (CVD) ma ọ bụ nsị anụ ahụ (PVD). N'ebe a, anyị na-ahụ usoro PVD. A na-etinye ihe ntinye n'ime ihe ndozi ... ma tinye n'ime oven. Ihe mkpuchi nke dị mkpa na-eme ka ntinye ahụ sie ike ma sie ike. Nke a bụkwa ebe ntinye na-enweta agba ya kpọmkwem.

Ọ bụ ezie na a na-enyocha ihe ntinye n'ime ụlọ nyocha mgbe niile n'oge usoro ahụ dum, a na-eji aka nyochaa ya ọzọ tupu ejiri laser akara ma kpochie ya. Mgbe akara akara, igbe isi awọ dị njikere iziga ndị nrụpụta gburugburu ụwa.

OGE OGE: 2024-01-01