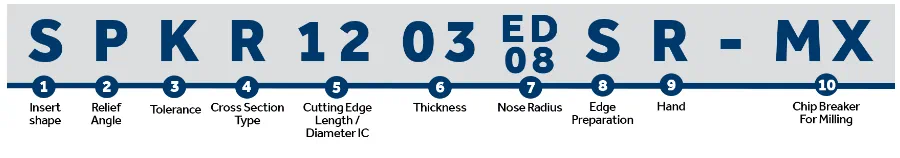

When you see a milling cutter blade, you may come across the term "ISO code." But what does this code really mean? What message does it send? Understanding the ISO code for milling inserts is essential to select the right tool for the milling operation and get the best results.

Whether you are an experienced machinist looking to expand your knowledge, or a newcomer looking for a milling operation, this guide will demystify the ISO code for milling inserts here.

We will explore the interpretation of the code, how the code interprets important information about the geometry, material, and cutting characteristics of the insert. By the end, you will have the knowledge to interpret the code, enabling you to select the perfect milling insert to optimize your machining process.

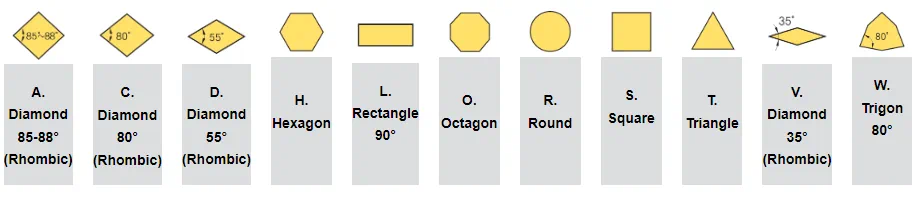

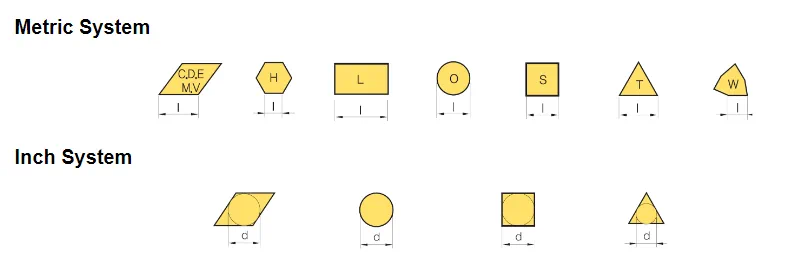

1.The shape of the blade

The first part of the ISO code for milling inserts is about insert shape and style.

It starts with a letter indicating the shape of the blade, such as R for round, S for square, T for triangle, D for diamond, or C for diamond.

This gives an information about the overall form of the blade, helping with quick identification. By looking at the first letter of the milling insert ISO code, it is possible to get an initial idea of the shape of the insert, which plays an important role in determining its specific application and cutting capabilities.

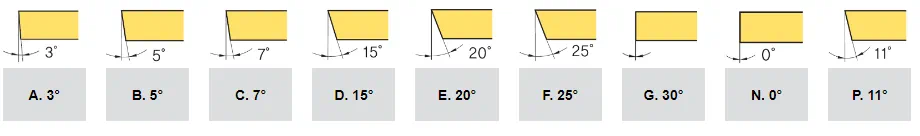

2.Blade rear corner

The second letter of the milling insert ISO specification refers to the back corner of the insert.

Milling the blade rear angle is essential for efficient and successful machining operations.

It plays a vital role in chip formation, tool life, cutting force and surface finish. Understanding the influence of rear angle and choosing the right rear angle can greatly improve processing performance, productivity and finished product quality.

3.Tolerance

Position 3 determines the tolerance of the milling insert.

Tolerance refers to the allowable variation in the size or measurement value of the manufactured part. The tolerance class specified in ISO position 3 for milling inserts helps to determine the accuracy of the insert size and the constant level of machining quality.

Tolerances of milling blades are important for several reasons. First of all, it ensures proper fit and compatibility with the tool holder, promoting stable and safe clamping during machining. Second, precise tolerances contribute to dimensional accuracy, allowing for constant and reliable machining results.

In addition, tight tolerances allow interchangeability within the tool system, minimizing downtime. They also affect tool life and performance, as well as surface finish and accuracy.

4.Section type

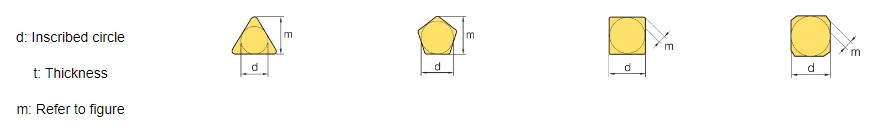

ISO position 4 refers to the cross-sectional type of milling insert.

The cross-section type of a milling insert refers to the shape of its cutting edge when viewed from a vertical angle. It affects the cutting action and performance of the blade.

Common cross section types include squares, circles, triangles, rhomboids, and pentagons. Machinists should consider the cross section type when selecting the insert to ensure the best cutting capability and chip removal for their specific machining tasks and materials.

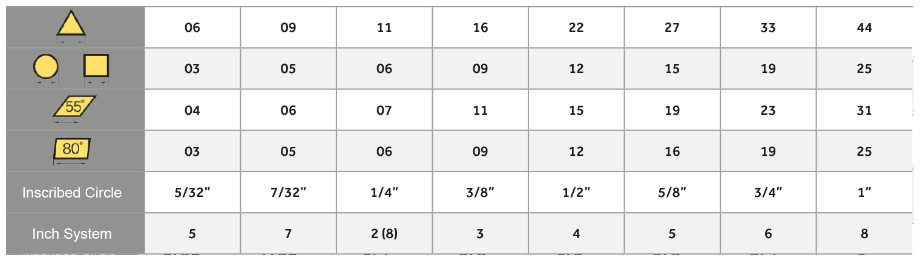

5.Cutting edge length / diameter IC

Position 5 provides detailed information on the dimensions of the milling insert or the length of the cutting edge.

The cutting edge length of the milling insert is an important factor that directly affects the cutting performance and efficiency of the insert.

The longer cutting edge length allows for a larger contact area between the blade and the workpiece, thereby increasing productivity and improving material removal. It enables the insert to come into contact with a larger material surface area, reducing the number of machining tracks required to complete the machining operation.

Therefore, choosing the right tip length is essential to achieve optimal cutting performance, maximize productivity and ensure a cost-effective milling operation.

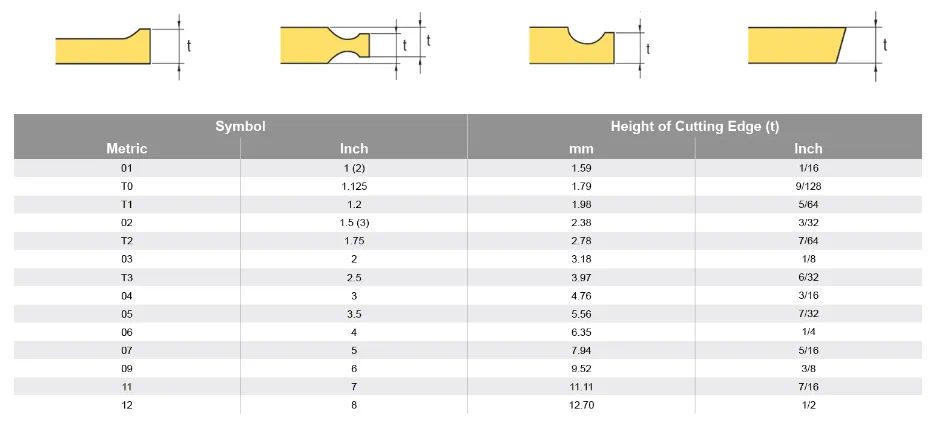

6.Thickness

Position 6 clarifies the thickness of the milling insert.

In the cutting process, the thickness of the insert is crucial to its strength and stability. Thicker inserts perform well under heavy loads, improving performance and minimizing the risk of cutting edge breakage.

Generally, double-sided (negative) blades have a greater thickness than single-sided (positive) blades.

Therefore, choosing the right thickness is essential to achieve the best cutting performance, productivity and desired quality of the machined parts.

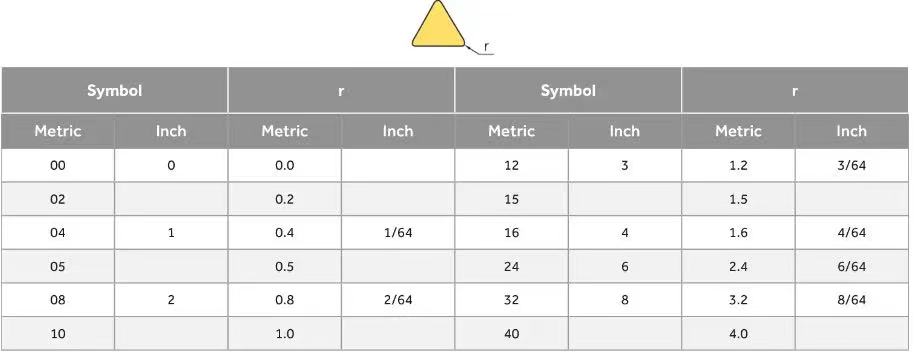

7.Tip fillet radius

Coming to number 7, we will encounter information about the blade radius.

The radius of the milling insert is important for precise and efficient machining operations, while being able to apply the radius to your cutting. Smaller radii tend to favor finer cutting / finishing, while larger radii are more suitable for heavy metal removal due to the strength of the blade angle.

The radius also affects the cutting force of the insert, chip control, tool life, and surface finish. Careful consideration of the right nose radius according to specific machining requirements and materials is essential to achieve optimum performance, tool life and surface finish in milling operations.

8.Blade information

Milling insert ISO 8 usually provides information about the blade.

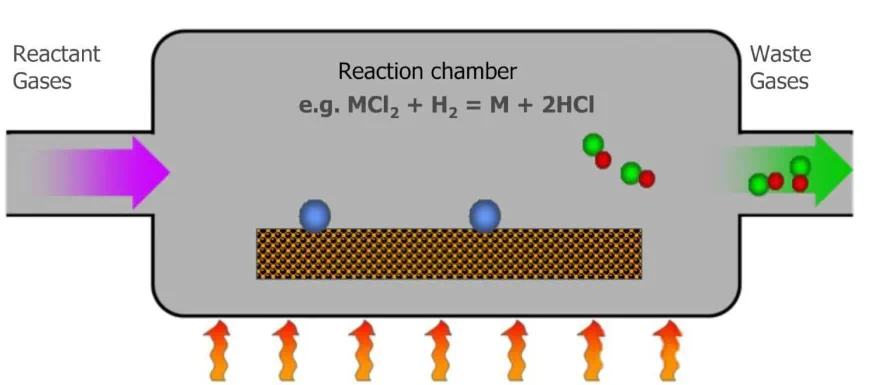

Edge preparation of milling inserts refers to the intentional additional treatment of the insert's edge before it is used in a milling operation. It involves applying a specific treatment or coating to improve the performance and durability of the blade.

By carefully selecting and applying the appropriate edge technology, machinists can improve machining performance, productivity, and tool life while maintaining high-quality surface finish and dimensional accuracy.

Image

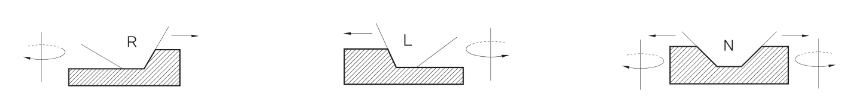

9.Left hand blade, right hand blade

The direction or direction of the cutting edge of the milling cutter blade and its corresponding shape.

It determines whether the blade is designed to rotate right-handed (clockwise) or left-handed (counter-clockwise) during milling.

Using inserts with the correct hand orientation is essential for efficient and accurate machining results.

10.Chip breaking trough design

Number 10 reflects the blade chip breaking design.

Chip breaking design of milling insert refers to the specially designed geometric shape on the surface of the insert and the cutting edge during the milling process, which helps to control chip formation.

It plays a vital role in chip control, reducing the formation of chip blockage, tool sticking and chip buildup.

A well-designed chip breaking design is essential to ensure a smooth and reliable machining process.

Summary

Understanding the ISO code for milling inserts is like deciphering a secret language that is key to successful milling operations and tool selection.

Each bit of the code provides valuable insights into blade shape, dimensions, tolerances and material grades.

By revealing the meaning behind each part, the machinist can confidently select the right milling insert, ensure compatibility with the machining settings, and achieve the desired results in terms of performance, accuracy, and tool life.

With this knowledge, you are ready to decode the milling insert ISO code and unlock the potential of your milling process.

POST TIME: 2024-11-17