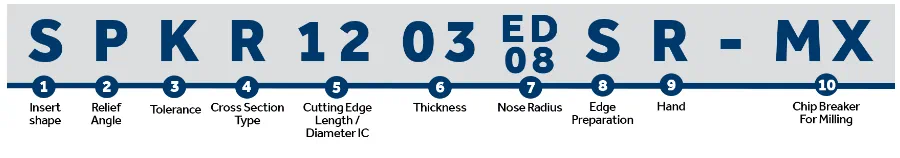

Paunoona chigayo chekucheka blade, unogona kusangana neshoko rekuti "ISO code." Asi kodhi iyi inomborevei chaizvo? Inotumira meseji yei? Kunzwisisa iyo ISO kodhi yekuisa milling kwakakosha kuti usarudze chishandiso chakakodzera chegayo uye uwane mibairo yakanaka.

Kunyangwe iwe uri machinist ane ruzivo ari kutsvaga kuwedzera ruzivo rwako, kana mutsva ari kutsvaga basa rekugaya, gwara iri rinobvisa iyo ISO kodhi yekugayo kuisa pano.

Isu tichaongorora kududzirwa kwekodhi, kuti iyo kodhi inodudzira sei ruzivo rwakakosha nezve geometry, zvinhu, uye kucheka maitiro ekuisa. Pakupera, iwe uchave neruzivo rwekududzira iyo kodhi, ichikugonesa iwe kuti usarudze yakaringana milling yekuisa kuti ukwidzise maitiro ako ekugadzira.

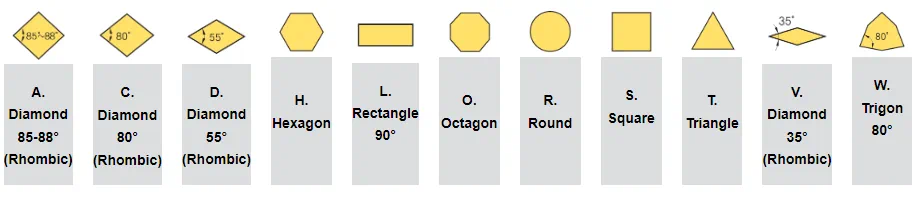

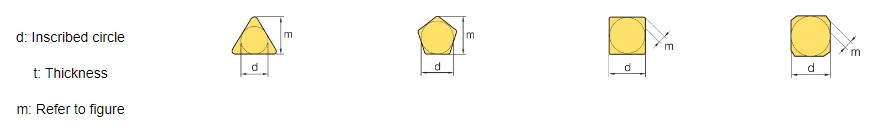

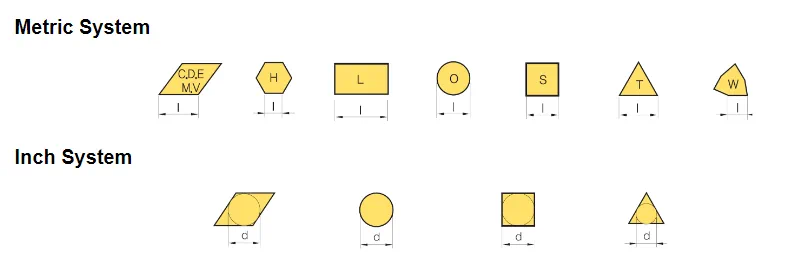

1.Chimiro chebadza

Chikamu chekutanga cheiyo ISO kodhi yekuisa milling ndeye yekuisa chimiro uye chimiro.

Rinotanga nebhii rinoratidza chimiro chebadza, rakaita saR redenderedzwa, S rekona, T rekona, D redhaimani, kana C redhaimani.

Izvi zvinopa ruzivo rwezvese fomu reblade, zvichibatsira nekuzivikanwa nekukurumidza. Nekutarisa tsamba yekutanga yekugaya isa ISO kodhi, zvinokwanisika kuwana yekutanga pfungwa yechimiro chekuisa, iyo inoita basa rakakosha pakuona kwayo chaiyo kushandiswa uye kucheka kugona.

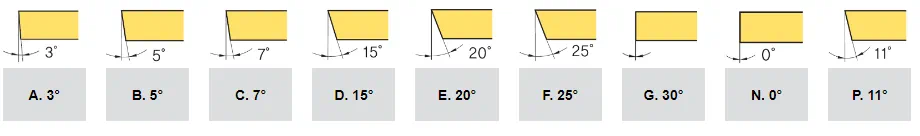

2.Blade kumashure kwekona

Ruvara rwechipiri rwekugayo inoisa ISO tsanangudzo inoreva kukona yekuseri kweiyo yekuisa.

Kugaya iyo blade rear angle kwakakosha kune inoshanda uye yakabudirira machining mashandiro.

Inoita basa rakakosha mukugadzira chip, hupenyu hwezvishandiso, simba rekucheka uye kupera kwepasi. Kunzwisisa pesvedzero yekona yekumashure uye kusarudza iyo chaiyo yekumashure kona kunogona kuvandudza zvakanyanya mashandiro ekugadzirisa, kugadzira uye kupera kwechigadzirwa mhando.

3.Tolerance

Position 3 inotarisa kushivirira kwechigayo chekuisa.

Kushivirira kunoreva musiyano unotenderwa muhukuru kana kuyerwa kukosha kwechikamu chakagadzirwa. Kirasi yekushivirira inotsanangurwa muISO chinzvimbo 3 yekuisa milling inobatsira kuona iko kurongeka kwesaizi yekuisa uye chiyero chinogara chiripo chemhando yekugadzira.

Kushivirira kwezviyo zvekugaya kwakakosha kune zvikonzero zvakati wandei. Chekutanga pane zvese, inovimbisa kwakaringana uye kuenderana nemubati wemidziyo, inosimudzira yakagadzikana uye yakachengeteka clamping panguva yekugadzira. Chechipiri, kushivirira chaiko kunobatsira pakurongeka kwedimensional, zvichibvumira mhedzisiro uye yakavimbika machining mhedzisiro.

Pamusoro pezvo, kushivirira kwakasimba kunobvumira kuchinjika mukati meiyo sisitimu yekushandisa, kuderedza nguva yekudzikira. Izvo zvakare zvinokanganisa hupenyu hwezvishandiso uye kuita, pamwe nekupedza kwepamusoro uye kurongeka.

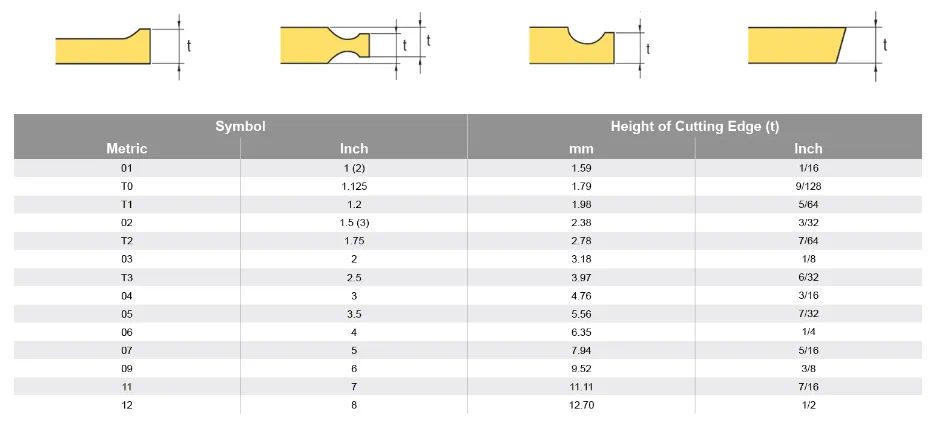

4.Section type

ISO chinzvimbo 4 inoreva iyo muchinjika-chikamu mhando yekugadzika kuisa.

Rudzi rwemuchinjiko rwechigayo (cross-section type of a milling insert) zvinoreva maumbirwo emupendero wayo kana ichionekwa kubva pakona. Inobata chiito chekucheka uye kushanda kweblade.

Mhando dzemuchinjiro dzakajairwa dzinosanganisira masikweya, madenderedzwa, matatu, rhomboids, uye pentagoni. Machinist anofanirwa kufunga nezve muchinjiko chikamu chemhando pakusarudza iyo yekuisa kuti ive nechokwadi chekucheka kugona uye chip kubviswa kune avo chaiwo machining mabasa uye zvinhu.

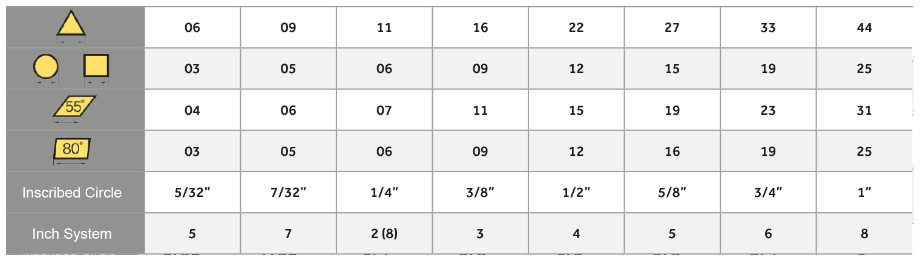

5.Kucheka kumucheto kureba / dhayamita IC

Position 5 inopa ruzivo rwakadzama pane zviyero zvegiyo yekuisa kana kureba kwekucheka kumucheto.

Iyo yekucheka kumucheto kureba kwekuisa milling chinhu chakakosha chinokanganisa zvakananga kuita kwekucheka uye kugona kwekupinza.

Iyo yakareba yekucheka kumucheto kureba inobvumira nzvimbo yakakura yekubatanidza pakati peblade uye workpiece, nekudaro kuwedzera kubereka nekuvandudza kubviswa kwezvinhu. Iyo inogonesa iyo yekuisa kuti ibatane neyakakura zvinhu pamusoro penzvimbo, ichidzikisa huwandu hwemachining tracks anodiwa kupedzisa machining oparesheni.

Naizvozvo, kusarudza kureba kwetipi chaiko kwakakosha kuti uwane yakakwana yekucheka kuita, kuwedzera kugadzirwa uye kuve nechokwadi chekushanda-zvinobudirira kwekugaya.

6.Kukora

Position 6 inojekesa ukobvu hwechigayo chekuisa.

Muchigadziro chekucheka, kukora kwekuisa kwakakosha kune simba rayo uye kugadzikana. Kuiswa kwakakora kunoita zvakanaka pasi pemitoro inorema, kuvandudza mashandiro uye kuderedza njodzi yekucheka kumucheto.

Kazhinji, mativi maviri-ane (negative) blades ane ukobvu hukuru kupfuura rimwe-sided (positive) blades.

Naizvozvo, kusarudza ukobvu hwakakodzera kwakakosha kuti uwane yakanakisa yekucheka kuita, kubereka uye inodiwa mhando yezvikamu zvemichina.

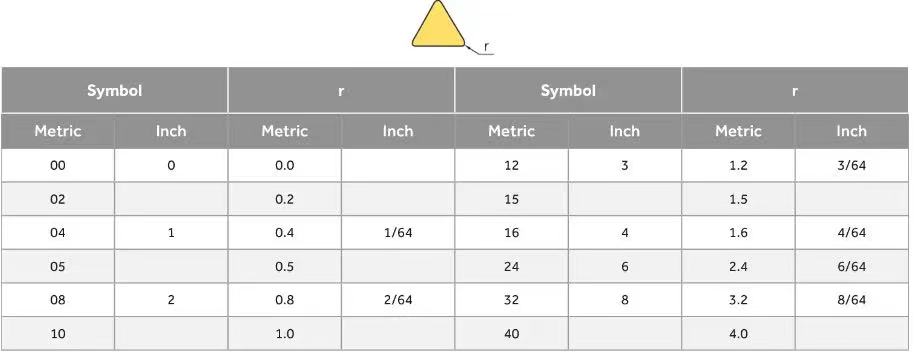

7.Tip fillet radius

Kuuya kune nhamba 7, isu tichasangana neruzivo nezve blade radius.

Iyo radius yekuisa milling yakakosha kune chaiyo uye inoshanda machining mashandiro, uku uchikwanisa kuisa radius pakucheka kwako. Diki radii inowanzofarira kucheka kwakanaka / kupedzisa, nepo radii yakakura ichinyanya kukodzera kubviswa kwesimbi inorema nekuda kwesimba rekona yeblade.

Iyo radius inobatawo simba rekucheka rekuisa, chip control, hupenyu hwechishandiso, uye kupera kwepamusoro. Kunyatsotariswa kweredhiyo yemhino yekurudyi zvinoenderana nezvinodiwa zvemuchina uye zviwanikwa zvakakosha kuti uwane kuita kwakanyanya, hupenyu hwechishandiso uye kupera kwepamusoro mukushanda kwekugaya.

8.Blade ruzivo

Milling isa ISO 8 kazhinji inopa ruzivo nezve blade.

Kugadzirira kweEdge kwekuisa milling kunoreva kuwedzeredzwa kwekuwedzera kurapwa kwemupendero wekupinza usati washandiswa mukugayo. Zvinosanganisira kushandisa kurapa kwakananga kana kupfekedza kuvandudza mashandiro uye kusimba kweblade.

Nekunyatsosarudza uye nekushandisa iyo yakakodzera kumucheto tekinoroji, machinists anogona kuvandudza machining mashandiro, kugadzirwa, uye hupenyu hwezvishandiso uku vachichengetedza yepamusoro-yemhando yepamusoro kupedzisa uye kurongeka chaiko.

Image

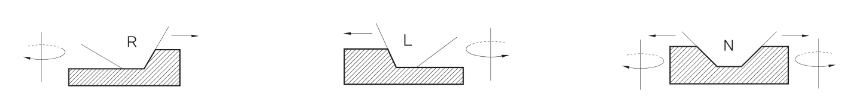

9.Kuruboshwe ruoko, rudyi blade

Kutungamira kana kutungamira kwekucheka kumucheto kwechigayo chekucheka blade uye chimiro chayo chinowirirana.

Inotarisa kana blade yakagadzirirwa kutenderera kurudyi-kurudyi (wachi) kana kuruboshwe-ruoko (kutarisana-newachi) panguva yekugaya.

Kushandisa zvinoiswa neruvoko rwekumisikidza kwakakosha pakubudirira uye kwakaringana machining mhedzisiro.

10.Chip kutyora dhizaini

Nhamba yegumi inoratidza iyo blade chip breaking dhizaini.

Chip breaking dhizaini yekugayo yekuisa inoreva iyo yakanyatso gadzirwa geometric chimiro pamusoro peiyo yekuisa uye yekucheka mupendero panguva yekugaya, iyo inobatsira kudzora chip kuumbwa.

Inoita basa rakakosha mukudzora chip, kuderedza kuumbwa kwechip blockage, chishandiso chinonamira uye chip kuvaka.

Iyo yakanyatsogadzirwa chip breaking dhizaini yakakosha kuti ive yakatsetseka uye yakavimbika machining process.

Summary

Kunzwisisa kodhi yeISO yezvigayo zvinoiswa kwakafanana nekududzira mutauro wakavanzika unova wakakosha pakubudirira mashandiro ekugaya uye kusarudzwa kwezvishandiso.

Chimwe nechimwe chidimbu chekodhi chinopa ruzivo rwakakosha muchimiro cheblade, hukuru, kushivirira uye mamakisi emidziyo.

Nekuburitsa zvinoreva kuseri kwechikamu chega chega, machinist anogona kusarudza aine chivimbo chekuisa chigayo, kuve nechokwadi chekuenderana nemagadzirirwo emuchina, uye kuwana mhedzisiro inodiwa maererano nekuita, chokwadi, uye hupenyu hwekushandisa.

Neruzivo urwu, iwe wakagadzirira kudhiraivha kugayo isa ISO kodhi uye kuvhura kugona kwegayo yako maitiro.

PASI NGUVA: 2024-11-17