Sikuthatha sikuse kwindawo yokuvelisa i-WATT Carbide e-Zhuzhou ukuze ubone ukuba ufakelo lwenziwa njani. Jonga ukuba yenziwa njani!

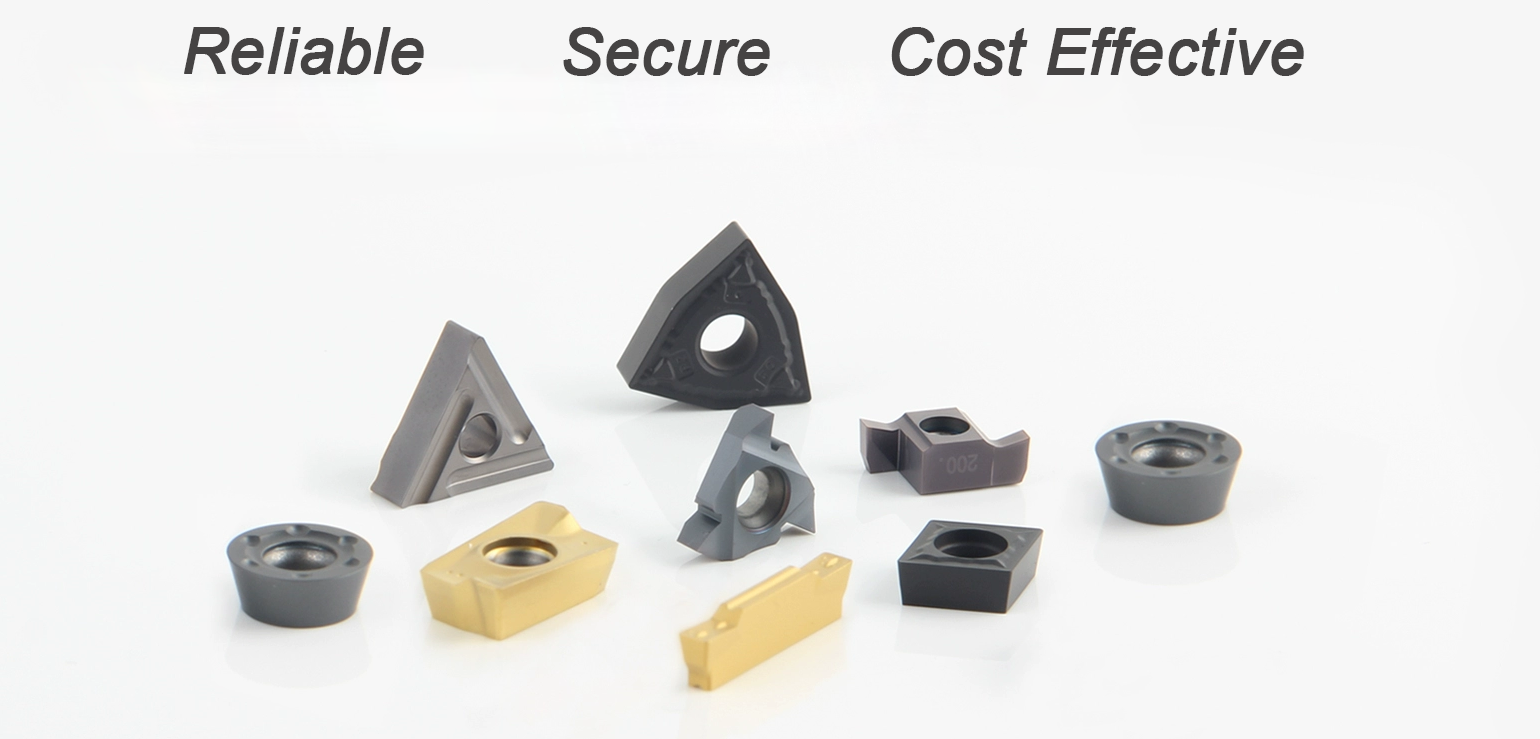

I-Transcript Phantse yonke into eyenziwe ngentsimbi ifakwe ngomatshini. Ukufakwa kufuneka kumelane nobushushu obugqithisileyo kunye nokunyanzeliswa, ngoko ke yenziwe ngeyona nto inzima kakhulu emhlabeni.

Ufakelo oluqhelekileyo lwenziwe nge-80% ye-tungsten carbide kunye ne-matrix yensimbi edibanisa iinkozo ze-carbide eziqinileyo, apho i-cobalt ixhaphake kakhulu. Kuthatha ngaphezu kweentsuku ezimbini ukuvelisa i-insert, ngoko yinkqubo enzima.

Kwindawo yokugcina impahla, umqolo emva komqolo wezinto ezikrwada zipakishwe. I-tungsten carbide esiyisebenzisayo iphuma kubaboneleli abakhethwe ngononophelo; ibhetshi nganye ivavanywa ngokucokisekileyo elebhu. Ezinye iindlela zokupheka ziqulethe ixabiso elincinci lezithako ezikhethiweyo ezongezwa ngesandla. Izithako eziphambili zikhutshwa ngokuzenzekelayo kwiindawo zokumisa ezahlukeneyo ecaleni komgca wokulinganisa. Kwigumbi lokugaya izithako zixutywe kwi-particle efunekayo kunye ne-ethanol, amanzi kunye ne-organic binder.

Le nkqubo ithatha kwiiyure ezisibhozo ukuya kwii-55, kuxhomekeke kwiresiphi. Udaka lumpontshelwa kwisitshizi sokutshiza apho irhasi yenitrogen eshushu itshizwa ukuze ibe ngumphunga i-ethanol kunye nomxube wamanzi. Xa umgubo womile, uqulathe iigranules ezingqukuva ezinobukhulu obufanayo. Isampulu ithunyelwa elebhu ukuze kujongwe umgangatho. Imigqomo yeekhilogram ezili-100 zepowder elungele ukucofa ifika kumatshini ocinezelayo. Isibophelelo esongeziweyo kwigumbi lokusila sisibophelelo esibamba umgubo kunye emva kokucinezela.

Ukuya kwiitoni ezili-12 zoxinzelelo zisetyenziswa, kuxhomekeke kuhlobo lokufaka. Isibophelelo esongeziweyo kwigumbi lokusila yinto ebambe umgubo kunye emva kokucinezela. Inkqubo izenzekelayo ngokupheleleyo. Isifakelo ngasinye silinganiswa kwaye ngamaxesha athile alawulwa ngokubonakalayo ngumsebenzisi. Ukufakwa okucinezelweyo kubuthathaka kakhulu kwaye kufuneka kuqiniswe kwi-oven sintering. Le nkqubo ithatha malunga neeyure ezili-13 kubushushu obumalunga ne-1,500 degrees Celsius. Izinto ezifakelweyo zifakwe kwimveliso eqinileyo yesamente-carbide, ephantse yaqina njengedayimani.

Isibophelelo sezinto eziphilayo siyatshiswa kwaye isifakelo sicutheka malunga nesiqingatha sobukhulu baso bokuqala. Ubushushu obugqithisileyo buphinde busetyenziswe ukufudumeza indawo ebusika, kwaye buzipholise ehlotyeni. Ukufakwa kumhlaba, ngamnye, kwiindidi ezahlukeneyo zoomatshini bokugaya ukufezekisa ubungakanani obuchanekileyo, ijometri kunye nokunyamezela. Njengoko i-carbide efakwe ngesamente inzima kakhulu, idiski ene-150 yezigidi zeedayimani ezincinci zamashishini, zisetyenziselwa ukuyicola. I-carbide engaphezulu iyahlaziywa, kunye neoli esetyenziselwa ukusika ulwelo.

Uninzi lwezinto ezifakelwayo zigqunywe, mhlawumbi ngekhemikhali yokubeka umphunga (CVD) okanye i-physical vapor deposition (PVD). Apha, sibona inkqubo yePVD. Izinto ezifakwayo zifakwa kwizixhobo... kwaye zifakwe kwi-oveni. Uluhlu oluncinci lwengubo lwenza ukuba ukufakwa kube nzima kwaye kube nzima. Apha kukwalapho ufakelo lufumana umbala walo othile.

Nangona ufakelo luye lwahlolwa elebhu rhoqo ngexesha lenkqubo yonke, luvavanywa ngesandla kwakhona phambi kokuba imakishwe kwaye ipakishwe. Emva kokufakwa ilebhile, iibhokisi ezingwevu zilungele ukuthunyelwa kubavelisi kwihlabathi liphela.

IXESHA LOKUTHUMELA: 2024-01-01