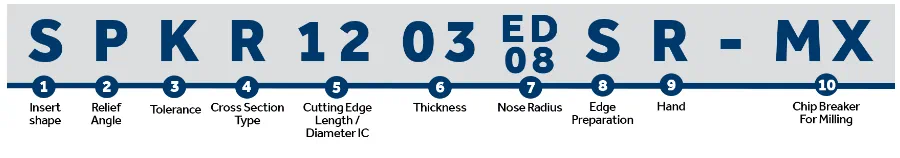

Xa ubona iblade yokusika i-milling, ungadibana negama elithi "ISO code." Kodwa ithetha ukuthini le khowudi ngokwenene? Ithumela umyalezo othini? Ukuqonda ikhowudi ye-ISO yokufakwa kokugaya kubalulekile ukukhetha isixhobo esifanelekileyo somsebenzi wokusila kwaye ufumane iziphumo ezilungileyo.

Nokuba ungowomatshini onamava ojonge ukwandisa ulwazi lwakho, okanye ungumntu omtsha okhangela umsebenzi wokusila, esi sikhokelo siya kuphelisa ikhowudi ye-ISO yokufakwa kokugaya apha.

Siza kuhlolisisa ukuchazwa kwekhowudi, indlela ikhowudi echaza ngayo ulwazi olubalulekileyo malunga nejometri, izinto eziphathekayo, kunye neempawu zokusika zokufaka. Ekugqibeleni, uya kuba nolwazi lokutolika ikhowudi, ekuvumela ukuba ukhethe ukufakela okugqibeleleyo kokugaya ukwenza inkqubo yakho yobuchwephesha.

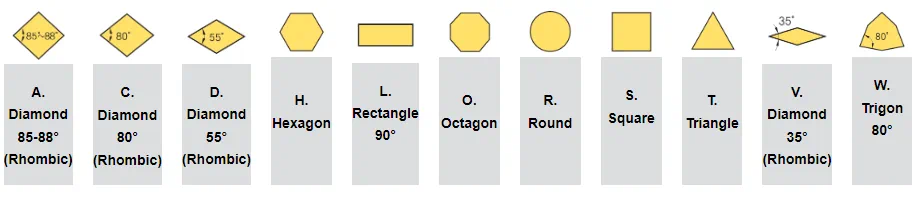

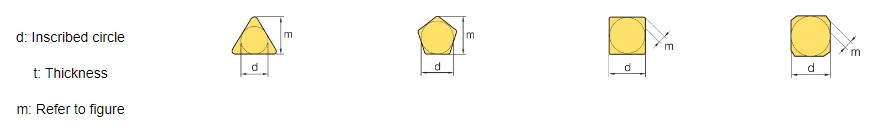

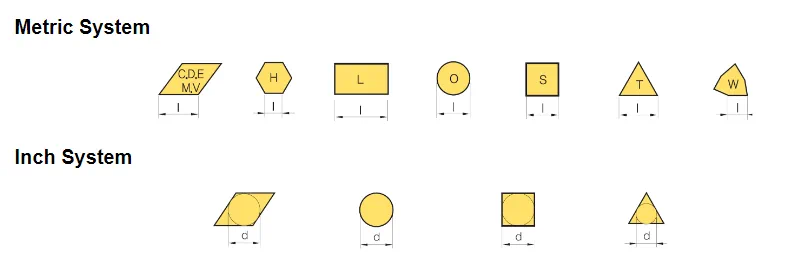

1.Imilo yencakuba

Inxalenye yokuqala yekhowudi ye-ISO yokufakwa kokugaya imalunga nokufaka imilo kunye nesimbo.

Uqala ngonobumba obonisa imilo yencakuba, njengo-R ongqukuva, S osikwere, T othetha unxantathu, uD wedayimani, okanye uC wedayimani.

Oku kunika ulwazi malunga nefom epheleleyo ye-blade, inceda ngokuchongwa ngokukhawuleza. Ngokujonga ileta yokuqala yokugaya ikhowudi ye-ISO yokugaya, kunokwenzeka ukuba ufumane ingcamango yokuqala yesimo sofakelo, esidlala indima ebalulekileyo ekunqumeni isicelo sayo esithile kunye nobuchule bokusika.

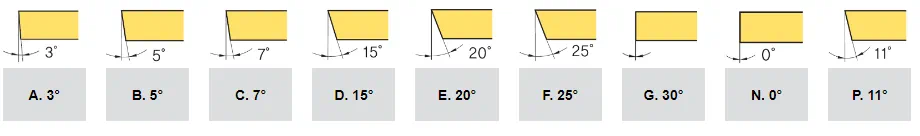

2.Blade kwikona yangasemva

Unobumba wesibini wofakelo lokusila ucaciso lwe-ISO lubhekisa kwikona yangasemva yofakelo.

Ukugaya i-engile yangasemva ye-blade kubalulekile ekusebenzeni ngokufanelekileyo kunye nempumelelo yomatshini.

Idlala indima ebalulekileyo ekwenziweni kwetshiphu, ubomi besixhobo, amandla okusika kunye nokugqiba umphezulu. Ukuqonda impembelelo ye-angle yangasemva kunye nokukhetha i-angle engasemva echanekileyo kunokuphucula kakhulu ukusebenza kokulungiswa, ukuveliswa kunye nomgangatho wemveliso ogqityiweyo.

3.Tolerance

Isikhundla sesi-3 simisela ukunyamezelwa kokufakwa kokugaya.

Ukunyamezela kubhekiselele kwinguqu evumelekileyo kubungakanani okanye ixabiso lomlinganiselo wenxalenye eyenziweyo. Iklasi yokunyamezela echazwe kwi-ISO isikhundla se-3 sokufakwa kokugaya inceda ukucacisa ukuchaneka kobungakanani bokufaka kunye nenqanaba eliqhubekayo lomgangatho womatshini.

Ukunyamezelwa kwee-blades zokugaya kubalulekile ngenxa yezizathu ezininzi. Okokuqala, iqinisekisa ukufaneleka okufanelekileyo kunye nokuhambelana nomphathi wesixhobo, ukukhuthaza ukubethelwa okuzinzileyo kunye nokukhuselekileyo ngexesha lokucoca. Okwesibini, ukunyamezela okuchanekileyo kunegalelo ekuchanekeni kwe-dimensional, okuvumela ukuba kubekho iziphumo eziqhubekayo kunye nezithembekileyo zomatshini.

Ukongezelela, ukunyamezela okuqinileyo kuvumela ukutshintshisana ngaphakathi kwenkqubo yesixhobo, ukunciphisa ixesha lokunciphisa. Zikwachaphazela ubomi besixhobo kunye nokusebenza, kunye nokugqitywa komphezulu kunye nokuchaneka.

4.Uhlobo lwecandelo

Isikhundla se-ISO sesi-4 sibhekisa kuhlobo olunqamlezayo lwecandelo lokusila.

Uhlobo lwe-cross-section ye-milling insert ibhekiselele kwimilo ye-cut cut edge xa ijongwa kwi-angle ethe nkqo. Ichaphazela isenzo sokusika kunye nokusebenza kwe-blade.

Iindidi eziqhelekileyo zecandelo lomnqamlezo zibandakanya izikwere, izangqa, oonxantathu, iirhomboids, kunye neepentagons. Oomatshini kufuneka baqwalasele uhlobo lwecandelo lomnqamlezo xa bekhetha ukufakwa ukuze kuqinisekiswe amandla okusika kunye nokususwa kwe-chip kwimisebenzi yabo yomatshini kunye nezinto eziphathekayo.

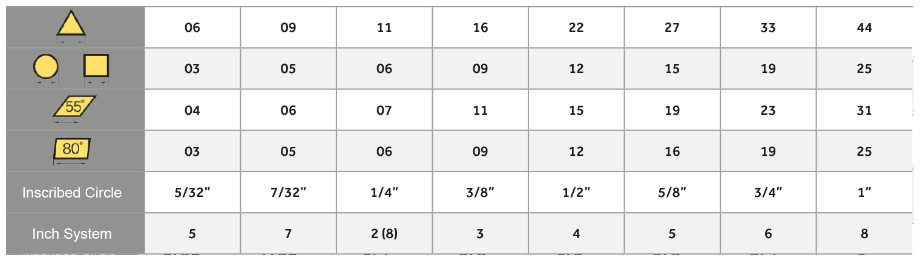

5.Cutting edge ubude / ububanzi IC

Isikhundla se-5 sinikezela ngolwazi oluthe kratya kwimilinganiselo yokufakwa kokugaya okanye ubude becala lokusika.

Ubude obunqamlekileyo bokufakwa kokugaya yinto ebalulekileyo echaphazela ngokuthe ngqo ukusebenza kokusika kunye nokusebenza kakuhle kokufakela.

Ubude obude bokusika buvumela indawo enkulu yokudibanisa phakathi kwe-blade kunye ne-workpiece, ngaloo ndlela ukwandisa imveliso kunye nokuphucula ukususwa kwezinto. Yenza ukuba ufakelo ludibane nommandla omkhulu wezinto eziphathekayo, ukunciphisa inani lamathrekhi omatshini afunekayo ukugqiba umsebenzi womatshini.

Ke ngoko, ukukhetha ubude bencam echanekileyo kubalulekile ukufezekisa ukusebenza kakuhle kokusika, ukwandisa imveliso kunye nokuqinisekisa ukusebenza kokugaya okunexabiso eliphantsi.

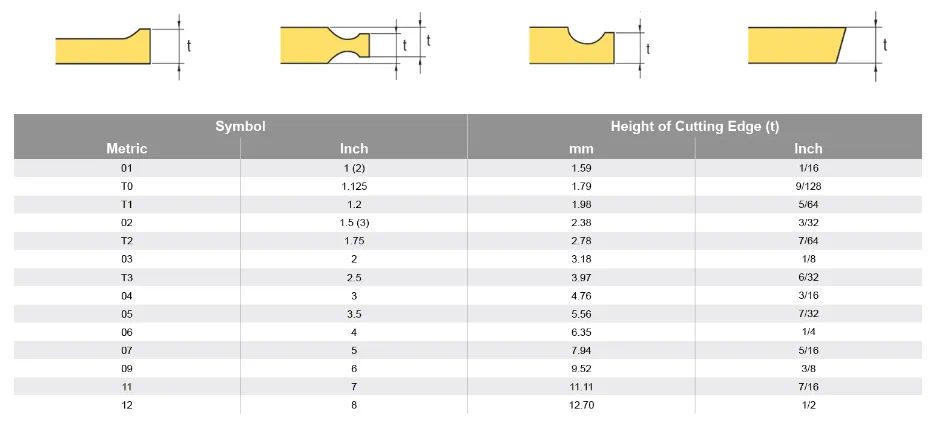

6.Ukutyeba

Isikhundla sesi-6 sicacisa ubukhulu bokufakwa kokusila.

Kwinkqubo yokusika, ubukhulu bokufakwa bubalulekile kumandla ayo kunye nokuzinza. Ukufakwa okutyebileyo kuqhuba kakuhle phantsi kwemithwalo enzima, ukuphucula ukusebenza kunye nokunciphisa umngcipheko wokuqhawula.

Ngokubanzi, iincakuba ezinamacala amabini (negative) zinobukhulu obukhulu kunecala elinye (elilungileyo).

Ke ngoko, ukukhetha ubukhulu obufanelekileyo kubalulekile ukufezekisa ukusebenza kakuhle kokusika, imveliso kunye nomgangatho ofunwayo wamacandelo omatshini.

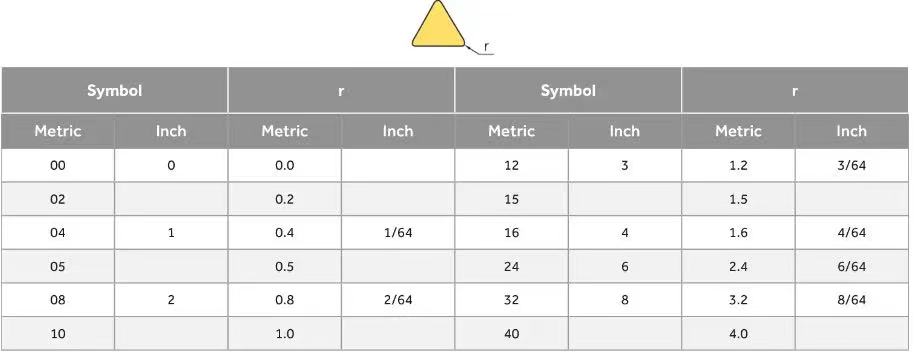

7.Tip fillet radius

Ukuza kwinombolo yesi-7, siya kudibana nolwazi malunga neradiyasi yeblade.

Iradiyasi yokufaka i-milling ibalulekile ekusebenzeni okuchanekileyo kunye nokusebenza kakuhle, ngelixa ukwazi ukusebenzisa i-radius ekusikeni kwakho. Irediya ezincinci zikholisa ukuthanda ukusika / ukugqiba okucolekileyo, ngelixa irediya ezinkulu zifaneleke ngakumbi ukususwa kwentsimbi enzima ngenxa yokomelela kwe-engile yeblade.

Iradiyasi ikwachaphazela amandla okusika okufakwayo, ulawulo lwetshiphu, ubomi besixhobo, kunye nokugqiba komphezulu. Ukuqwalaselwa ngononophelo kwerediyasi yempumlo yasekunene ngokweemfuno ezithile zomatshini kunye nemathiriyeli kubalulekile ukufezekisa ukusebenza kakuhle, ubomi besixhobo kunye nokugqitywa komphezulu kwimisebenzi yokugaya.

8.Blade ulwazi

Ukufakwa kokugaya i-ISO 8 ngokuqhelekileyo kunika ulwazi malunga nencakuba.

Ukulungiswa komda kofakelo lokusila kubhekiselele kunyango olongezelelweyo ngabom kumphetho wokufaka phambi kokuba usetyenziswe kumsebenzi wokusila. Kubandakanya ukusebenzisa unyango oluthile okanye ukugubungela ukuphucula ukusebenza kunye nokuqina kwe-blade.

Ngokukhetha ngononophelo kunye nokusebenzisa itekhnoloji efanelekileyo yomphetho, oomatshini banokuphucula ukusebenza koomatshini, imveliso, kunye nobomi besixhobo ngelixa begcina umgangatho ophezulu wokugqitywa komphezulu kunye nokuchaneka komda.

Umfanekiso

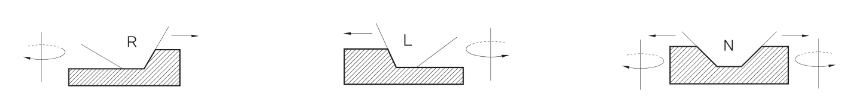

9.I-blade yesandla sasekhohlo, i-blade yesandla sasekunene

Isalathiso okanye isalathiso somgca wokusika we-milling cutter blade kunye nesimo sayo esihambelanayo.

Imisela ukuba i-blade yenzelwe ukujikeleza ngasekunene (kwiwotshi) okanye ngasekhohlo (ngokuchasene newotshi) ngexesha lokusila.

Ukusebenzisa ukufakwa ngokuqhelaniswa nesandla esichanekileyo kubalulekile kwiziphumo zomatshini ezisebenzayo nezichanekileyo.

10.Chip uyilo lokuqhekeza umkhombe

Inombolo 10 ibonisa uyilo lokuqhawuka kwencakuba yetshiphu.

I-chip breaking design yokufaka i-milling ibhekisela kwimilo yejometri eyilwe ngokukodwa kumphezulu wofakelo kunye nomphetho wokusika ngexesha lenkqubo yokusila, enceda ukulawula ukubunjwa kwe-chip.

Idlala indima ebalulekileyo kulawulo lwetshiphu, ukunciphisa ukwakheka kokuvaleka kwetshiphu, ukuncamathelisa isixhobo kunye nokwakhiwa kwetshiphu.

Uyilo oluyilwe kakuhle lokuqhekeza itshiphu luyimfuneko ukuze kuqinisekiswe inkqubo yomatshini egudileyo nethembekileyo.

Isishwankathelo

Ukuqonda ikhowudi ye-ISO yokufakwa kokugaya kufana nokucacisa ulwimi oluyimfihlo olungundoqo ekusebenzeni okuyimpumelelo kunye nokukhetha izixhobo.

Isuntswana ngalinye lekhowudi libonelela ngeembono ezixabisekileyo kwimilo ye-blade, imilinganiselo, ukunyamezela kunye namabakala ezinto eziphathekayo.

Ngokutyhila intsingiselo emva kwenxalenye nganye, umatshini unokukhetha ngokuzithemba ukufakwa kokugaya okufanelekileyo, ukuqinisekisa ukuhambelana nezicwangciso ze-machining, kunye nokufezekisa iziphumo ezifunwayo ngokubhekiselele ekusebenzeni, ukuchaneka, kunye nobomi besixhobo.

Ngolu lwazi, ukulungele ukucacisa ikhowudi yokusila yokufaka i-ISO kwaye uvule amandla enkqubo yakho yokusila.

IXESHA LOKUTHUMELA: 2024-11-17