Sikuyisa esikhungweni sokukhiqiza se-WATT Carbide e-Zhuzhou ukuze ubone ukuthi okufakwayo kwenziwa kanjani. Bheka ukuthi kwenziwa kanjani!

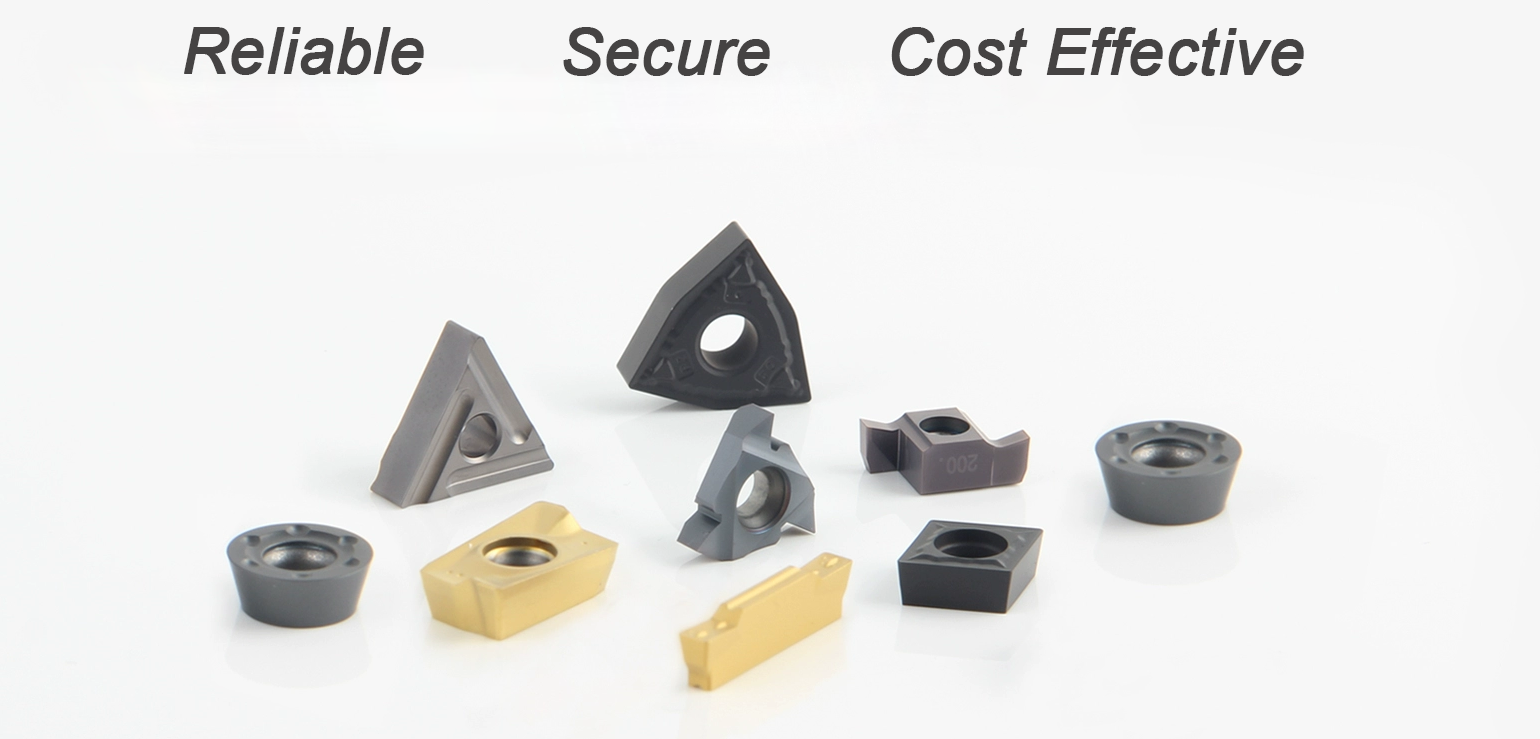

I-Transcript Cishe yonke into eyenziwe ngensimbi ifakwe ngomshini. Okufakiwe kufanele kumelane nokushisa okukhulu namandla, ngakho-ke kwenziwa ngenye yezinto eziqinile emhlabeni.

Ukufakwa okuvamile kwenziwa nge-tungsten carbide engu-80% kanye ne-matrix yensimbi ehlanganisa izinhlamvu ze-carbide eziqinile, lapho i-cobalt ivame kakhulu khona. Kuthatha izinsuku ezingaphezu kwezimbili ukukhiqiza okufakiwe, ngakho-ke kuyinqubo eyinkimbinkimbi.

Endaweni yokugcina impahla, umugqa ngemva komugqa wempahla eluhlaza kuyapakishwa. I-tungsten carbide esiyisebenzisayo ivela kubahlinzeki abakhethwe ngokucophelela; iqoqo ngalinye lihlolwe ngokucophelela elebhu. Ezinye zokupheka ziqukethe amanani amancane kakhulu wezithako ezikhethiwe ezengezwa ngesandla. Izithako eziyinhloko zibe sezikhishwa ngokuzenzakalelayo ezitobhini ezahlukene eduze komugqa wesisindo. Egunjini lokugaya izithako zigaywa zibe yizinhlayiyana ezidingekayo kanye ne-ethanol, amanzi kanye ne-organic binder.

Le nqubo ithatha amahora ayisishiyagalombili kuya kwangama-55, kuye ngokuthi iresiphi. I-slurry iphonswa endaweni yokomisa i-spray lapho igesi ye-nitrogen eshisayo ifuthwa khona ukuze kuhwamuke ingxube ye-ethanol namanzi. Uma impushana yomile, iqukethe ama-granules ayindilinga anosayizi abafanayo. Isampula ithunyelwa elebhu ukuze ihlolwe ikhwalithi. Imiphongolo engamakhilogremu angu-100 wempushana elungele ukucindezela ifika emshinini wokucindezela. Isibophelelo esinezezelwe egumbini lokugaya siyisibopho esibamba impushana ndawonye ngemva kokuyicindezela.

Kusetshenziswa amathani angu-12 okucindezela, kuye ngohlobo lokufaka. Isibophezelo esifakwe egunjini lokugaya yiso esibamba impushana ndawonye ngemva kokuyicindezela. Inqubo izenzakalelayo ngokuphelele. Okufakiwe ngakunye kuyakalwa futhi ngezikhawu ezithile kulawulwa ngokubukeka ngu-opharetha. Izinto ezifakiwe ezicindezelwe zintekenteke kakhulu futhi zidinga ukuqina kuhhavini elishisayo. Le nqubo ithatha cishe amahora angu-13 ekushiseni okungaba ngu-1,500 degrees Celsius. Okufakiwe kufakwe emkhiqizweni we-carbide oqinile kakhulu, ocishe uqine njengedayimane.

I-organic binder iyashiswa futhi okufakiwe kuncipha cishe kuhhafu wosayizi wayo wangempela. Ukushisa okweqile kusetshenziswa kabusha futhi kusetshenziselwa ukushisisa izakhiwo ebusika, futhi kuzipholise ehlobo. Ukufakwa kuphansi, ngamunye ngamunye, ezinhlotsheni ezahlukene zemishini yokugaya ukuze kuzuzwe usayizi oqondile, i-geometry nokubekezelelana. Njengoba i-carbide insert iqinile, idiski enamadayimane amancane ezimbonini ayizigidi ezingu-150, isetshenziselwa ukuyigaya. I-carbide eyeqile igaywa kabusha, kanye namafutha asetshenziswa njengoketshezi lokusika.

Iningi lezinto ezifakiwe zimboziwe, kungaba nge-chemical vapor deposition (CVD) noma i-physical vapor deposition (PVD). Lapha, sibona inqubo ye-PVD. Izinto ezifakwayo zifakwa ezintweni... …bese zifakwa kuhhavini. Ungqimba oluncane lwe-coating lwenza ukufaka kube nzima futhi kuqine. Yilapho futhi into efakiwe ithola khona umbala wayo othize.

Nakuba okufakiwe kuye kwahlolwa elebhu njalo phakathi nayo yonke inqubo, kuyahlolwa futhi mathupha ngaphambi kokuthi kumakwe futhi kupakishwe ilaser. Ngemuva kokufakwa ilebula, amabhokisi ampunga alungele ukuthunyelwa kubakhiqizi emhlabeni jikelele.

ISIKHATHI SOKUTHUMELA: 2024-01-01