Uma ubona i-milling cutter blade, ungase uhlangabezane negama elithi "ISO code." Kodwa isho ukuthini ngempela le khodi? Ithumela muphi umlayezo? Ukuqonda ikhodi ye-ISO yokufakwa kokugaya kubalulekile ukuze ukhethe ithuluzi elifanele lomsebenzi wokugaya futhi uthole imiphumela engcono kakhulu.

Kungakhathaliseki ukuthi ungumashini onolwazi ofuna ukwandisa ulwazi lwakho, noma usanda kufika ofuna umsebenzi wokugaya, lo mhlahlandlela uzokhipha ikhodi ye-ISO yokufakwayo kokugaya lapha.

Sizohlola ukuhunyushwa kwekhodi, ukuthi ikhodi ihumusha kanjani ulwazi olubalulekile mayelana nejometri, izinto ezibonakalayo, nezici zokusika zokufaka. Ekugcineni, uzoba nolwazi lokuhumusha ikhodi, okukuvumela ukuthi ukhethe ukufakwa kokugaya okuphelele ukuze uthuthukise inqubo yakho yokwenza imishini.

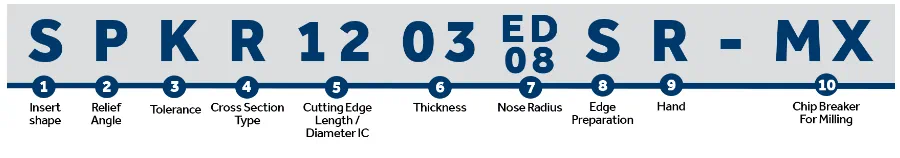

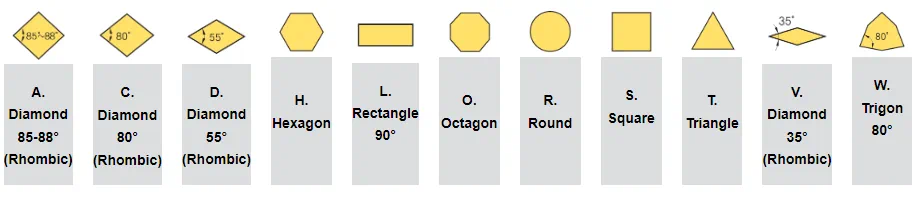

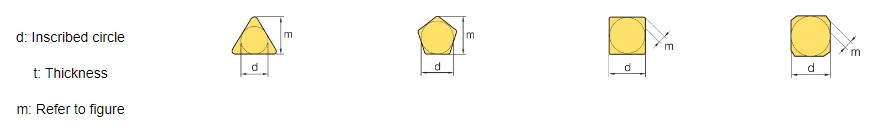

1.Ukuma kwe-blade

Ingxenye yokuqala yekhodi ye-ISO yokufakwa kokugaya imayelana nokufaka umumo nesitayela.

Iqala ngohlamvu olubonisa ukuma kwensingo, njengokuthi R oyindilinga, u-S wesikwele, u-T ongunxantathu, u-D owedayimane, noma u-C owedayimane.

Lokhu kunikeza ulwazi mayelana nefomu eliphelele le-blade, okusiza ngokuhlonza ngokushesha. Ngokubheka uhlamvu lokuqala lwekhodi ye-ISO yokugaya, kungenzeka ukuthi uthole umbono wokuqala wesimo sokufaka, esidlala indima ebalulekile ekunqumeni ukusetshenziswa kwayo okuqondile kanye nekhono lokusika.

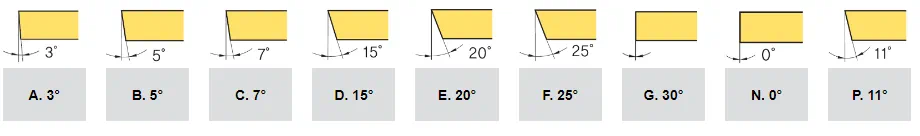

2.I-Blade ekhoneni elingemuva

Uhlamvu lwesibili lwe-ISO yokufakwayo kokugaya lubhekisela ekhoneni elingemuva lokufaka.

Ukugaywa kwe-engeli engemuva ye-blade kubalulekile ekusebenzeni kahle nangempumelelo komshini.

Idlala indima ebalulekile ekwakhiweni kwe-chip, impilo yamathuluzi, amandla okusika kanye nokuqedwa kwendawo. Ukuqonda umthelela we-engeli engemuva nokukhetha i-engeli engemuva efanele kungathuthukisa kakhulu ukusebenza kokucubungula, ukukhiqiza kanye nekhwalithi yomkhiqizo oqediwe.

3.Tolerance

Isikhundla sesi-3 sinquma ukubekezelelana kokufakwayo kokugaya.

Ukubekezelela kusho ukuhluka okuvumelekile kusayizi noma inani lokulinganisa lengxenye ekhiqiziwe. Isigaba sokubekezelela esicaciswe ku-ISO isikhundla 3 sokufakwa kokugaya kusiza ukucacisa ukunemba kosayizi wokufaka kanye nezinga eliqhubekayo lekhwalithi yomshini.

Ukubekezelela ama-milling blades kubalulekile ngezizathu eziningana. Okokuqala nje, iqinisekisa ukulingana okufanele nokuhambisana nesiphathi samathuluzi, ikhuthaza ukugoqa okuzinzile nokuphephile ngesikhathi somshini. Okwesibili, ukubekezelelana okunembayo kunomthelela ekunembeni kobukhulu, okuvumela imiphumela yemishini engaguquki nethembekile.

Ngaphezu kwalokho, ukubekezelelana okuqinile kuvumela ukushintshashintsha ngaphakathi kwesistimu yamathuluzi, ukunciphisa isikhathi sokuphumula. Ziphinde zithinte impilo yamathuluzi nokusebenza, kanye nokuqedwa kwendawo nokunemba.

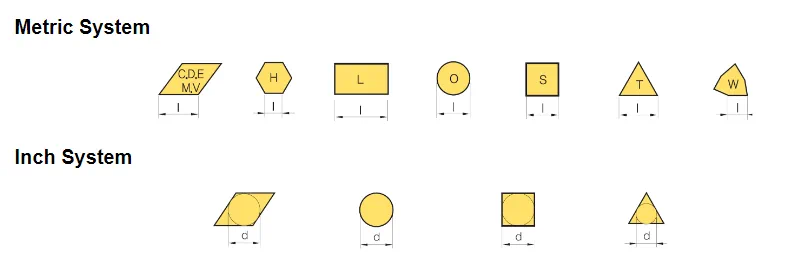

4.Uhlobo lwesigaba

I-ISO position 4 ibhekisela ohlotsheni olunezingxenye ezihlukene zokufakwa kokugaya.

Uhlobo lwesigaba esiphambanayo sokufakwa kokugaya lubhekisela ekumeni konqenqema lwaso uma lubukwa nge-engeli eqondile. Kuthinta isenzo sokusika nokusebenza kwe-blade.

Izinhlobo ezijwayelekile zesigaba esiphambanayo zifaka izikwele, imibuthano, onxantathu, ama-rhomboid, nama-pentagon. Omachini kufanele bacabangele uhlobo lwesigaba esiphambanayo lapho bekhetha okokufaka ukuze baqinisekise ikhono lokusika elingcono kakhulu kanye nokukhishwa kwe-chip ngemisebenzi yabo ethile yokumaka nezinto zokwakha.

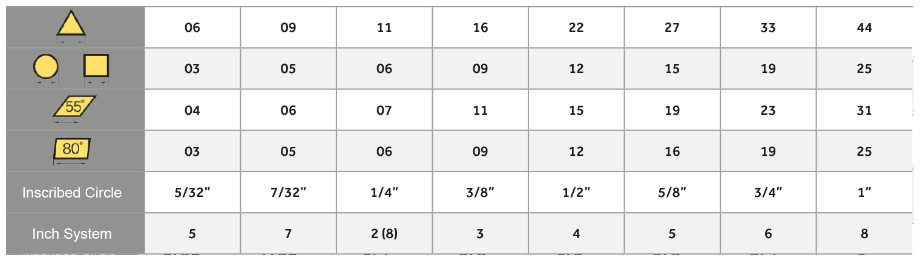

5.Ukusika ubude / ububanzi be-IC

Isikhundla sesi-5 sinikeza ulwazi oluningiliziwe ngobukhulu bokufakwa kokugaya noma ubude bomkhawulo wokusika.

Ubude obunqunyiwe bokufaka kokugaya kuyisici esibalulekile esithinta ngokuqondile ukusebenza kokusika nokusebenza kahle kokufaka.

Ubude bonqenqema olude buvumela indawo yokuxhumana enkulu phakathi kwe-blade nomsebenzi, ngaleyo ndlela kwandiswe ukukhiqiza nokuthuthukisa ukususwa kwezinto. Ivumela okokufaka ukuthintana nendawo enkulu yezinto ezibonakalayo, kunciphise inani lamathrekhi omshini adingekayo ukuze kuqedelwe umsebenzi womshini.

Ngakho-ke, ukukhetha ubude bethiphu obufanele kubalulekile ukuze kuzuzwe ukusebenza kahle kokusika, ukukhulisa ukukhiqiza nokuqinisekisa ukusebenza kokugaya okungabizi kakhulu.

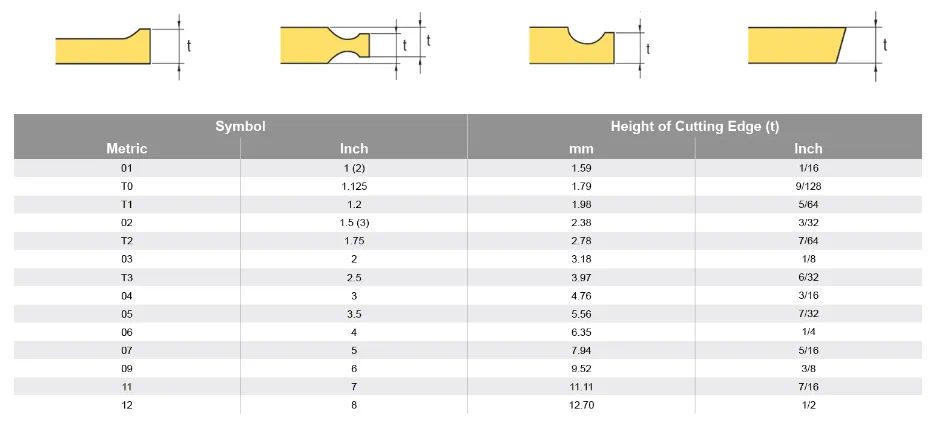

6.Ubukhulu

Isikhundla sesi-6 sicacisa ubukhulu bokufakwa kokugaya.

Enqubweni yokusika, ubukhulu bokufaka bubalulekile emandleni nasekuzinzeni kwayo. Ukufakwa okuwugqinsi kusebenza kahle ngaphansi kwemithwalo esindayo, kuthuthukisa ukusebenza nokunciphisa ubungozi bokunqamuka konqenqema.

Ngokuvamile, izindwani ezinezinhlangothi ezimbili (ezimbi) zinogqinsi olukhulu kunezindwani zohlangothi olulodwa (ezinhle).

Ngakho-ke, ukukhetha ukujiya okulungile kubalulekile ukuze kuzuzwe ukusebenza okuhle kakhulu kokusika, ukukhiqiza kanye nekhwalithi oyifunayo yezingxenye zomshini.

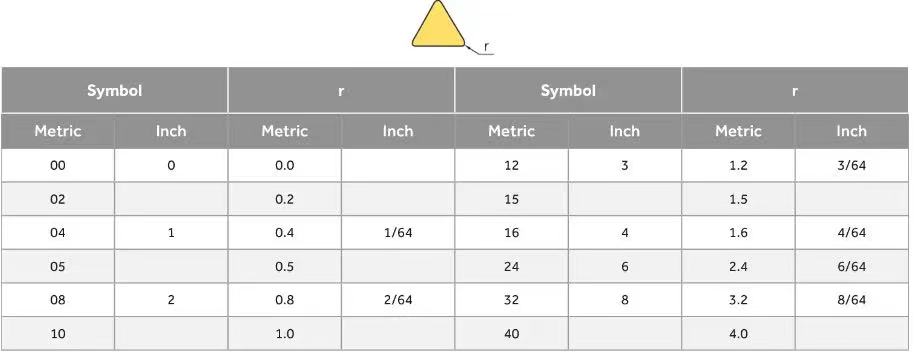

7.I-Tip fillet radius

Uma sifika kunombolo 7, sizohlangana nolwazi mayelana ne-blade radius.

Irediyasi yokufaka ukugaya ibalulekile ekusebenzeni komshini okunembayo nangempumelelo, kuyilapho ukwazi ukusebenzisa irediyasi ekusikeni kwakho. I-radii emincane ivame ukuthanda ukusika / ukuqedwa okucolisekileyo, kuyilapho ama-radii amakhulu afaneleka kakhulu ukususwa kwensimbi esindayo ngenxa yamandla e-engeli yeblade.

Irediyasi iphinda ithinte amandla okusika okufakwayo, isilawuli se-chip, impilo yamathuluzi, nokuqedwa kwendawo. Ukucatshangelwa ngokucophelela kwerediyasi yekhala elungile ngokuya ngezidingo ezithile zomshini nezinto zokwakha kubalulekile ukuze kuzuzwe ukusebenza okuphezulu, impilo yamathuluzi kanye nokuqedwa kwendawo ekusebenzeni kokugaya.

8.Imininingwane ye-blade

Ukufakwa kokugaya i-ISO 8 kuvame ukunikeza ulwazi mayelana ne-blade.

Ukulungiswa konqenqema kokufakwayo kokugaya kubhekisela ekuphathweni okwengeziwe ngamabomu konqenqema lokufaka ngaphambi kokuthi kusetshenziswe emsebenzini wokugaya. Kubandakanya ukusebenzisa ukwelashwa okuthile noma ukunamathela ukuze kuthuthukiswe ukusebenza nokuqina kwe-blade.

Ngokukhetha ngokucophelela nokusebenzisa ubuchwepheshe obufanele bonqenqema, ochwepheshe bemishini bangathuthukisa ukusebenza komshini, ukukhiqiza, nempilo yamathuluzi kuyilapho begcina ukuphela kwekhwalithi ephezulu nokunemba kobukhulu.

Isithombe

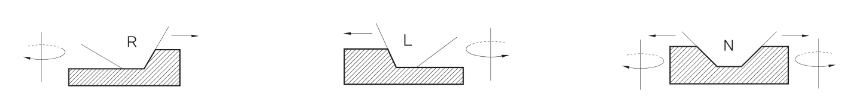

9.Isandla sokunxele, isandla sokudla

Isiqondiso noma isiqondiso somkhawulo wokusika we-milling cutter blade kanye nokuma kwayo okuhambisanayo.

Inquma ukuthi ingabe i-blade iklanyelwe ukuzungeza kwesokudla (ngokwewashi) noma kwesokunxele (ngokuphikisana nokuhamba kwewashi) ngesikhathi sokugaya.

Ukusebenzisa okufakwayo okuqondiswe ngesandla okulungile kubalulekile ukuze uthole imiphumela yomshini ephumelelayo nenembile.

10.I-Chip breaking trough design

Inombolo 10 ibonisa umklamo wokuphuka kwe-blade chip.

Idizayini ye-chip breaking ye-milling insert isho umumo wejometri oklanywe ngokukhethekile endaweni efakwayo kanye nonqenqema lokusika phakathi nenqubo yokugaya, okusiza ukulawula ukwakheka kwe-chip.

Idlala indima ebalulekile ekulawuleni ama-chip, ukunciphisa ukwakheka kokuvinjelwa kwe-chip, ukunamathela kwamathuluzi kanye nokwakhiwa kwe-chip.

Idizayini eklanywe kahle yokwephula i-chip ibalulekile ukuze kuqinisekiswe inqubo yokwenza imishini ebushelelezi nethembekile.

Isifinyezo

Ukuqonda ikhodi ye-ISO yokufakwa kokugaya kufana nokucacisa ulimi oluyimfihlo oluyisihluthulelo semisebenzi yokugaya eyimpumelelo nokukhetha kwamathuluzi.

Ingcezu ngayinye yekhodi inikeza imininingwane ebalulekile mayelana nokuma kwe-blade, ubukhulu, ukubekezelela kanye namabanga wezinto ezibonakalayo.

Ngokudalula incazelo engemuva kwengxenye ngayinye, umakhi angakhetha ngokuzethemba ukufakwa kokugaya okulungile, aqinisekise ukuhambisana nezilungiselelo zomshini, futhi afinyelele imiphumela efiselekayo mayelana nokusebenza, ukunemba, nempilo yamathuluzi.

Ngalolu lwazi, usukulungele ukunquma ikhodi ye-ISO yokugaya futhi uvule amandla enqubo yakho yokugaya.

ISIKHATHI SOKUTHUMELA: 2024-11-17